Reflow Marine

Leading the Field In Pipe Repair

About Reflow Marine

The Premiere Solution For Pipe Repair & System Rehabilitation

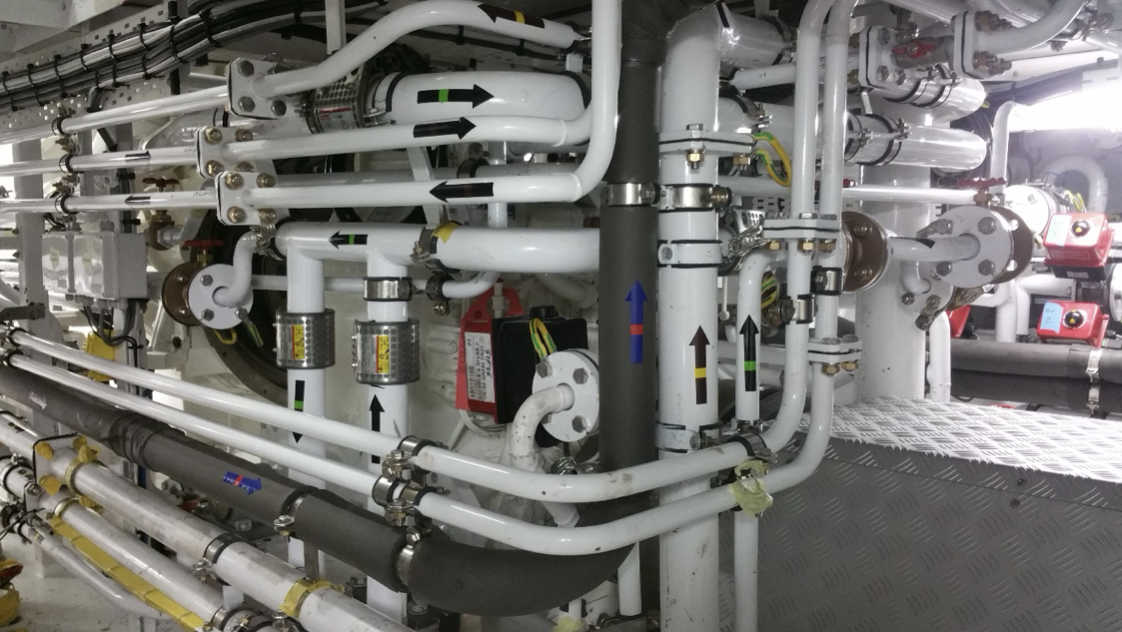

With years of cross sector experience and now focusing on the Marine sector, our unique innovative technology portfolio can repair both pressurised piping systems and non-pressurised piping systems using existing access points. We believe we offer the most viable and least disruptive option for pipe repair & rehabilitation. We ensure speed of repair and reduced costs against traditional pipe replacement.

Using market leading ‘Reflow Vortex’ technology we offer repair and future proofing for ‘Reflow Vortex Coating’, with additional services including ‘Structural Pipe Relining’ and ‘Epoxy Spray Lining’.

With project approvals with Lloyd’s Register along with product approvals with ABS and Bureau Veritas, we work with you to detect and prevent issues before they become detrimental to the operations of your yacht.

Our Pipe Lining System Benefits

Technology

Reflow Vortex Lining

Reflow’s Vortex coating process is an economical and efficient alternative to traditional pipe system replacement. Our technology restores aged, corroded piping systems.

The Reflow Vortex coating product and system is the result of over 7000 research hours dedicated to finding the perfect viscosity, air temperature cure time and delivery systems needed to achieve optimal pipe adherence that provides a longer-lasting piping solution. Once the epoxy coating is applied to the interior of the pipe, it will seal and protect the system from further deterioration, dramatically extending the system’s life.

The Reflow Vortex coating process is a non-invasive procedure permitting operations to continue preventing displacement, and reduced pipe system downtime.

We first drain the water out of the piping system and then run dry heated air through the pipes to ensure the removal of the moisture in the pipes. An abrasive is then added to clean removing all of the corrosion built up and create an anchor tooth for the epoxy to adhere to.

Once the pipe is fully cleaned we then apply an epoxy coating system to the piping system with filter instrument quality air until the pipe is fully coated creating a barrier coating eliminating future corrosion as per the below process.

Our Process

Where can the technology be used?

Our Systems have been developed to provide a fast, cost effective solution to extensive Marine problems. We not only have the ability to clean and dry the pipe, but also provide a unique lining system that coats the internal surface to provide a seamless barrier between the water and the pipe wall allowing systems to be restored in the shortest time possible.

The ability to rehabilitate piping systems without destruction has been revolutionary. The arduous need to close down entire operations for extensive time scales, halt business operations or relocate people as a result of traditional pipe repairs is a problem of the past.

The Reflow Vortex infrastructure repair uses non-invasive, non-destructive technology to repair inside the failing or aged pipe systems, greatly extending their useful lives. This innovative approach has a faster turnaround time and is approximately half cost of alternative, traditional pipe replacements. These pipe rehabilitation solutions can be used on many types of pressurised and non pressurised, closed loop piping systems across all Marine Systems.

Pipe Systems Covered

How it works

Why choose Reflow Marine

Rehabilitation of pipes offers many advantages compared to the complete replacement of infrastructure. ReFlow is the technology leader in applying epoxy coatings to pipes systems from Potable to Fire Suppression.

The ReFlow Vortex epoxy lining solution includes removing existing corrosion in the pipes and applying an epoxy coating without the need to take apart internal structures in-wall pipes. Pipe lining is less expensive than traditional pipe replacement costs. Lining is a non-invasive process, so there is minimal disruption. Reconstruction costs for replacing pipe are as much as 50 percent of direct pipe repair costs and Vortex lining eliminates the need for reconstruction. The process is effective in pipes from 10mm up to 300mm (12″) in diameter.

The unique characteristics of the ReFlow process make it feasible to line longer lengths of pipe through elbows, tees and unique system constructs. The epoxy coating process restores flow rates and prevents corrosion which would otherwise lead to pinhole leaks. We provide peace of mind that comes with preventing future leaks in hard to access areas within walls and ceilings.

Importantly we work with you to design and implement tailored processes to keep you operational and get you back to full systems speedily and cost effectively with the below benefits achieved.

Benefits of Reflow Lining

- 100% approved for drinking water and other systems

- All Deposits in pipe removed

- Creates Barrier between fluids and metal protecting from contaminations

- Polymer Lining allows for simple sterilization in cases of bacterial presence

- Repairs pinhole leaks that cause molding and rotting around the leak areas

- Strengthens systems in durable safe and eco friendly manner

Sample cross sector technology Case Studies

Cruise Ship Scupper pipes

A Cruise ship was suffering from leaking scupper pipes (deck drains) which had corroded and were inaccessible in many places due to other service pipes and cabling. Located above false ceiling panels in the busiest restaurant on the ship, which resulted in having to close off large sections each time it rained. Reflow Marine engineers employed a combination of methods including blue line drain liner which is a cured in place pipe liner and Mechanical brush coating with epoxy to repair and secure 100m of 3” upto 5” pipes with many bends, branches and inlets from deck above.

To replace the affected pipes was estimated at 6 weeks which would have had to include shutting down other services to remove pipes and cables to allow access to the drain pipes. We were able to line the pipes in 10 days with a 3 man team and no disruption to other services, all while the ship was at sea.

Black Water Pipes cleaned and relined on Super Yacht

Grade II Listed University Buildings relined

Scuppers, Potable water & Vents systems cleaned and Lined on Super Yacht

Potable Water Pipes in Multi-Million Euro Super yacht Relined

Grey Water, Ballast, Vents cleaned and Lined on Super Yacht

Cruise Liner Trial – Scupper pipes relined in place

Testimonials

JAMIE WILSON CE M/Y SIREN

Following several years of replacing sections of old Loro X pipework we contacted Reflow Marine who were contracted to carry out internal in place epoxy pipe lining.

The section of pipe in question was a very difficult section to access making replacement extremely difficult and costly.

To obtain access for replacement extensive carpentry and stone work would have been required to remove two bathrooms. The cost of this could have cost two, three or maybe even four times the price of relining the pipe in place. Combined with the challenge of matching 15 year old wood and stone material finishes and the down time, pipe lining was hands down the way to go.

The equipment and process employed by Reflow is state of the art. A full survey before, during after works was carried out. This highlighted some points of the pipe run which were a ticking time bomb of mess and hassle just waiting to happen. On completion this also provided proof that the internal coating was evenly applied to the whole section of the pipe run, with no blockages.

Reflow marines team were very conscious of the care and attention to detail required while working inside the interior of a Large Yacht. The team were easy to work with and they pushed ahead to complete the works in the time frame even when faced with unexpected surprises which occurred during the works.

We hope to see them back onboard in the future to carry out more works.

TOM CUMMING Chief Engineer M/Y Albatross

During some routine inspections we noticed some stainless-steel ballast pipe work leaking especially around the welds. We investigated further and found it was widespread throughout most of the pipe run. This was a great concern as the pipes run above the guest area deckheads as well as through technical areas.

We investigated several ways to repair this including like for like replacement, but this involved extensive interior dismantling as well as high risk hot works. Another option we looked into was replacing the existing pipe work with GRP. This seemed like a safer option but the GRP outside diameter was larger and would have meant lots of modifications to other equipment and bulkhead penetrations. Both of these options would have cost in excess of a million Euros.

We were then introduced to Reflow Marine who came onboard and carried out an initial camera survey and where confident that they could use their system to clean and coat the internal surface of the pipe work with minimal disruption at a fraction of the cost of my first 2 options. We shook hands and got planning the project for our next yard period. Reflow provided most of their own equipment with a few larger items needing to be rented via the shipyard. A lot a planning and discussions took place at the start of the project and to be honest I wasn’t sure it was going to work. The first length of pipe we done was about 15m long with several bends in it and rising 2 decks up. At the end of the pipe was a clear hose going to a recovery unit. We watched this hose in anticipation waiting for the blue epoxy coating to come out. It felt like hours but was probably more like 10 minutes but then it came out and coated the internal surfaces as it crept further and further towards the recovery unit. I was so happy to see the coating knowing that it had coated the internal surfaces from the tank to the exit. The other pipes went much quicker as all the calculations had been done. After allowing the epoxy to dry we surveyed the pipes again and could see the epoxy had coated the full internal surfaces. During the rest of my time onboard we never had any further issues with leaks.